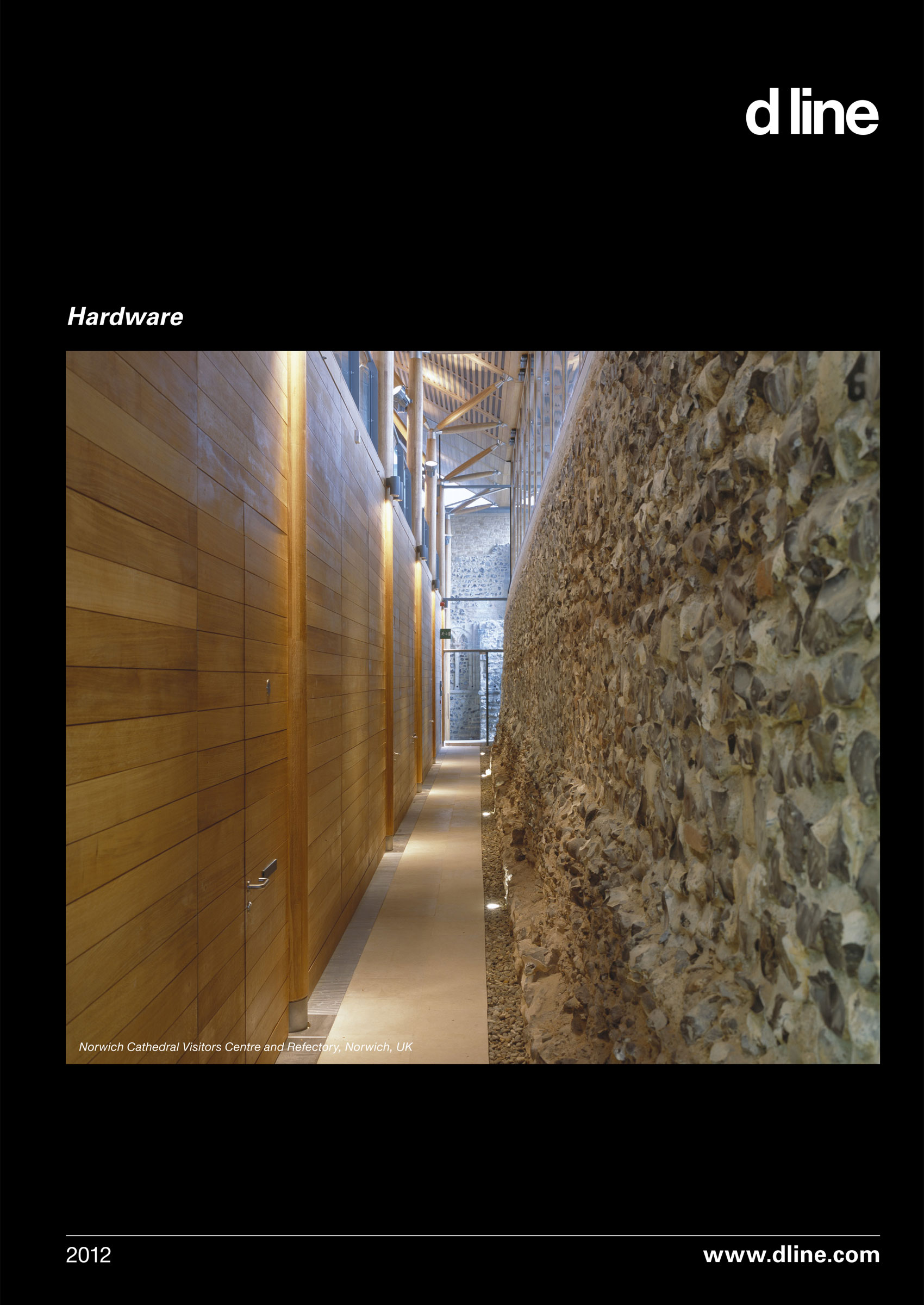

d line refined and redefined — Production

Though many d line products can be classed as industrial in both their design and their look, none of them are industrially made. They are hand crafted in our factory by our dedicated specialists. Tube cutting, welding, bending, grinding, polishing, assembly and packing – all of these stages of our production are undertaken by people, with the help of specialized machines, and each is carried out by one person before being passed on to the next. These tasks are truly specialized.

To achieve each tiny detail in a d line product, for example, special stamping and cutting tools have been developed just to create that single element. Meanwhile, to execute the grinding and polishing that results in our signature d line satin finish, a product is gently held by hand against a spinning wheel at specific angles and with equal pressure applied to every millimetre of the whole. This is carried out as four different steps before the product is wrapped for transportation to the next station. Labour-intensive processes such as these are critical for the achievement of precision and perfection. We think they’re worth it because the resulting products are truly enduring. Produced and edited by Norm Architects.